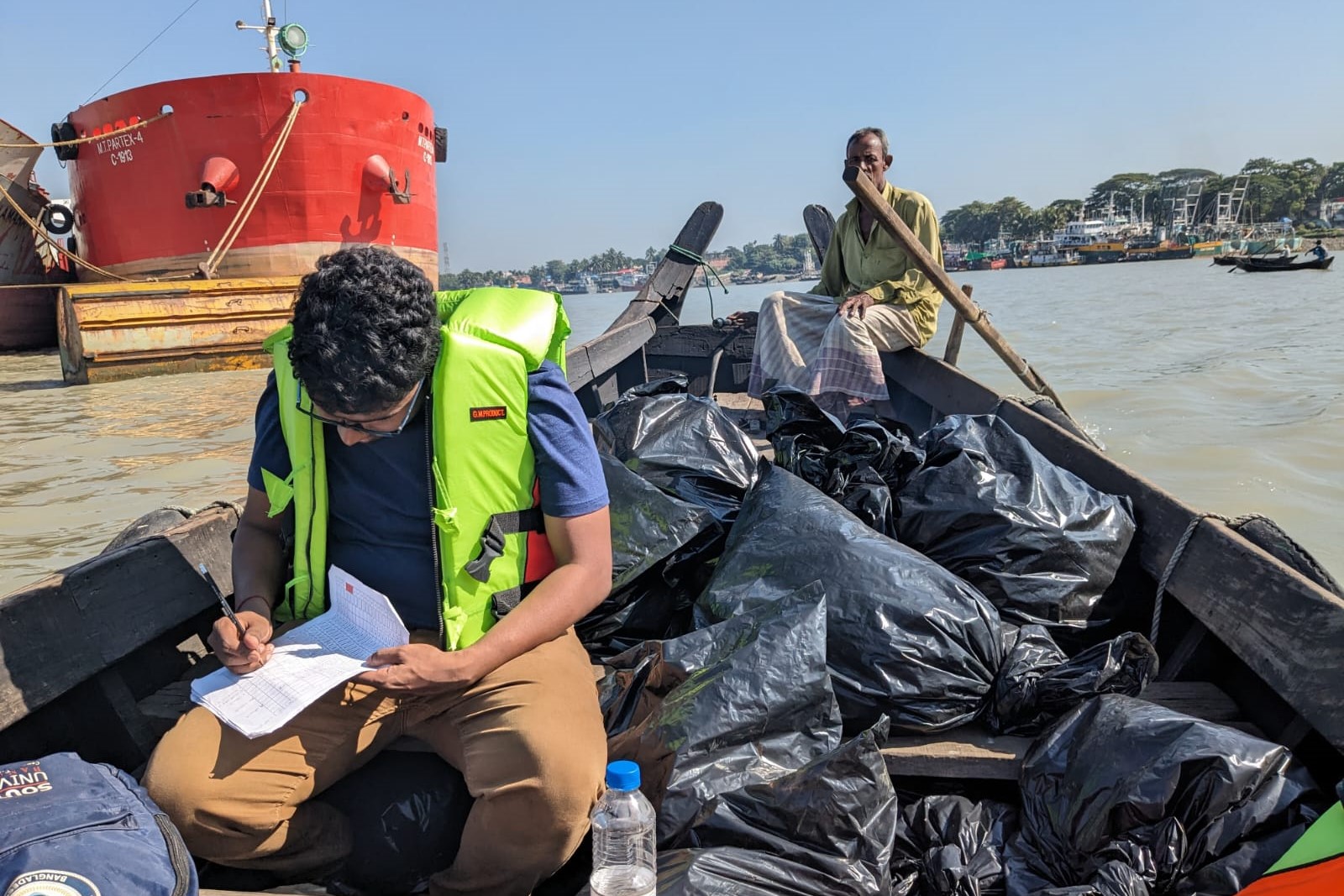

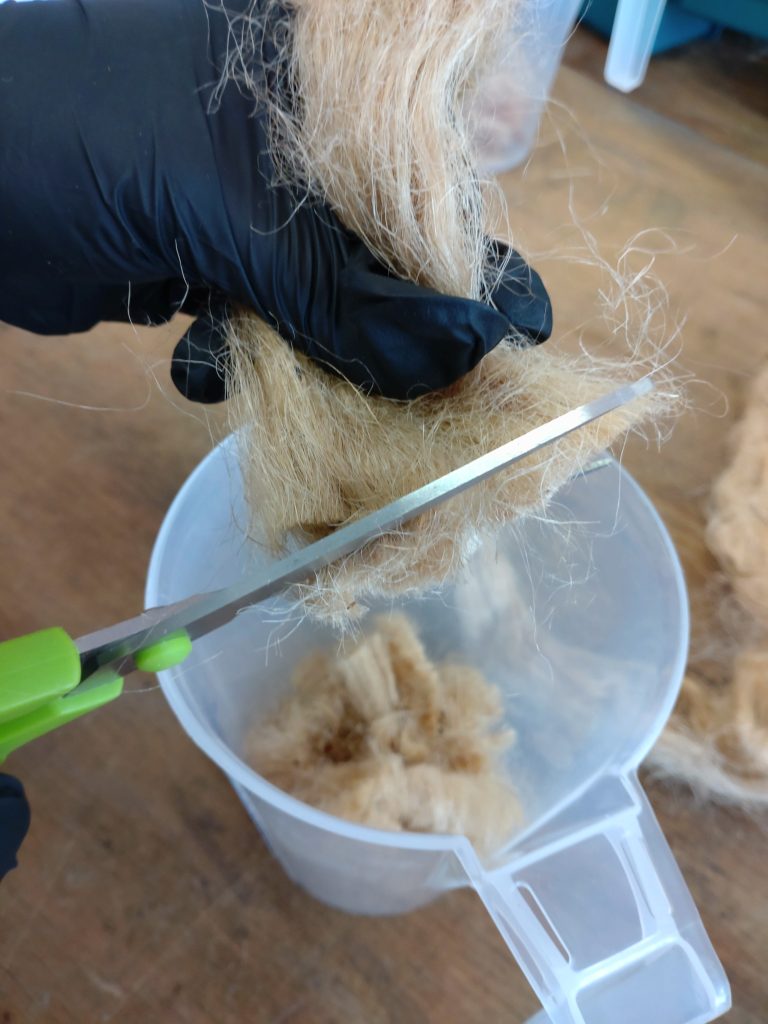

My recent visit to Germany was an enriching experience that provided me with valuable insights into advanced scientific and waste management practices. Over 15 days, my colleague Niloy Das and I, both from the SCIP Plastics Project, had the opportunity to conduct fermentation tests on jute in a state-of-the-art laboratory. Measuring the amount of carbon dioxide evolved during the anaerobic process was particularly significant. Incorporating this data into the life cycle assessment of jute products will enhance the understanding of their environmental impact.

One of the highlights of our trip was visiting the scalable mechanical processing plant named SWH. RAB in Halle-Lochau deals with 80,000 tons of residual waste, bulky waste, and industrial waste yearly. Witnessing the efficiency and effectiveness of the plant operations was inspiring.

Another remarkable experience was touring the organic waste treatment plant in Erfurt. It is interesting to find out their landfill after care and how the plant utilizes the organic waste to get compost and energy as a byproduct. Both plants were managed by a few highly skilled individuals, showcasing the potential for streamlined operations even with limited personnel. It is eye-catching to see the contrast between the waste management systems of Bangladesh and Germany.

We visited the METHA treatment plant (MEchanical Treatment and Dewatering of HArbour-sediments) in Hamburg, Germany’s biggest seaport. It’s intriguing to learn about the process of a highly technical dredged material management concept used to separate and manage sand, fine grain silt, and contaminated sediment of the River Elbe.

This experience will undoubtedly contribute to our efforts to enhance sustainability in plastic waste management in Bangladesh. Overall, this visit to Germany was not just an educational journey but also an inspiring one, fueling our passion for bringing innovative solutions to our home country.