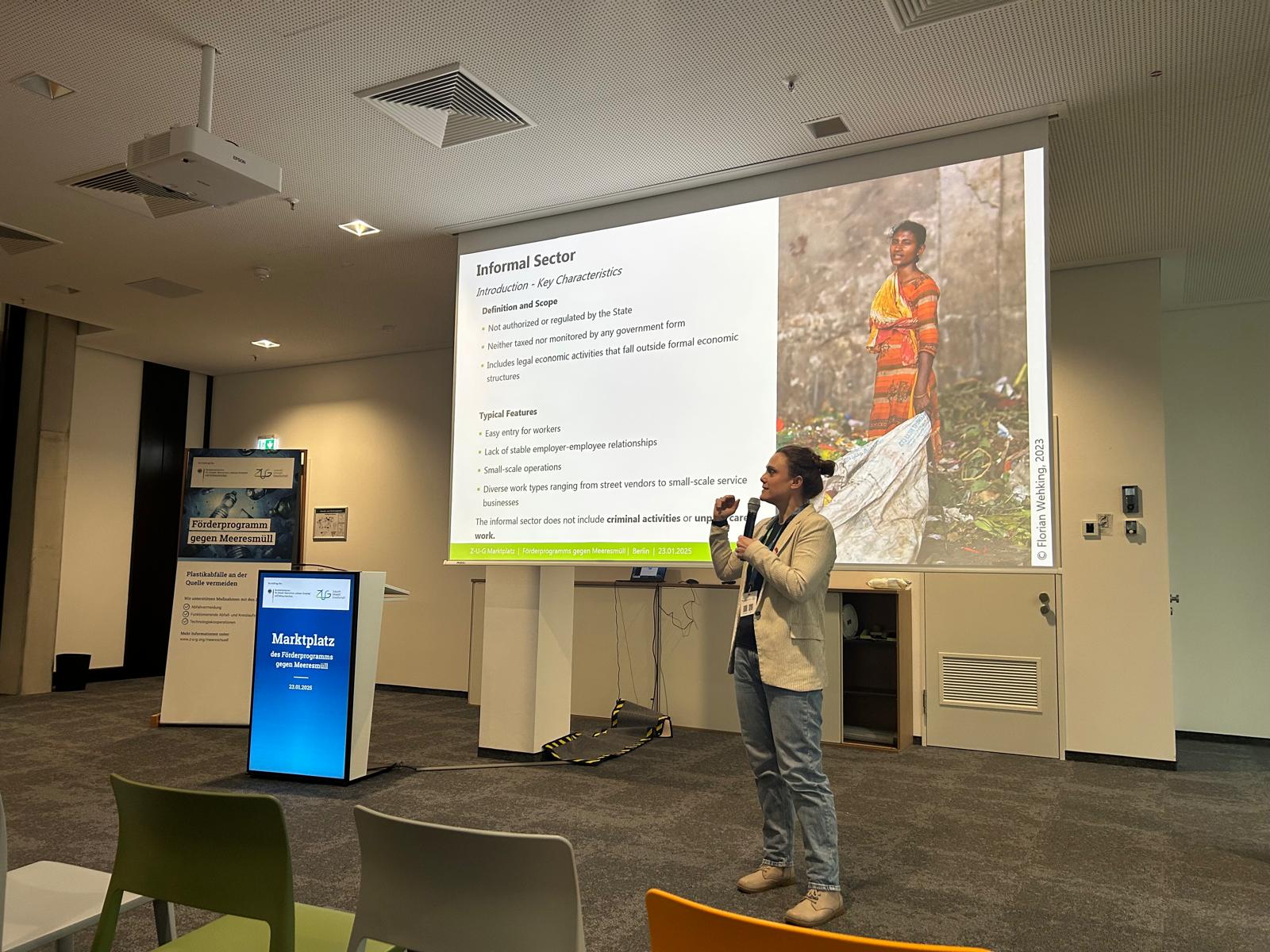

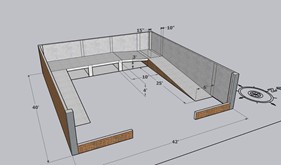

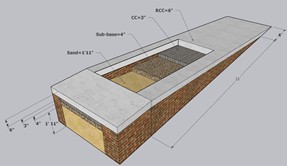

Khulna, Bangladesh – A pilot study conducted under the leadership of working group II has engaged four recycling shop owners in Khulna City to explore a sustainable business model for managing plastic waste. The initiative aims to curb plastic pollution in urban and marine environments by integrating the informal recycling sector with the city’s waste management system.

The core objective of the study was to channel mismanaged plastic waste toward proper collection, treatment, or disposal by the Khulna City Corporation (KCC). The project seeked to develop a Standard Operating Procedure (SOP) for handling non-valuable plastics, ensuring a structured and scalable approach to waste management.

Under the agreement, participating shop owners received monetary incentives for collecting dry, non-valuable plastics, such as single-use plastic bags, poly bags, and composite food wrappings. The project team together with KCC oversaw the timely and regular collection A key component of the project is fostering better communication between KCC and the informal recycling sector, strengthening collaboration for a cleaner city.

From August 2024 to February 2025 a total amount of 48 tons of plastic waste has found its way into the local waste management chain.

As part of the long-term strategy, evaluation results will be shared with KCC to guide the continued operation of this model. Additionally, the SCIP Plastics project will work to identify financial sources to sustain the initiative, ensuring its viability beyond the pilot phase.

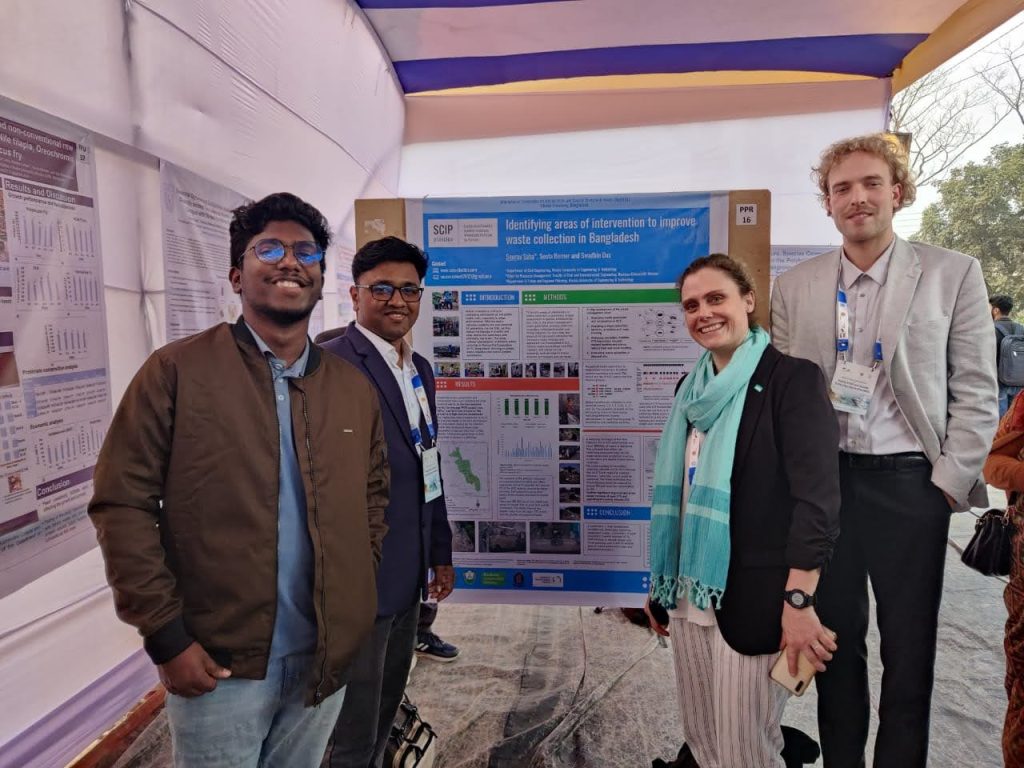

Scientific analysis, evaluation and publication is currently under progress and will be announced here in due course.

Scientific coordinators: Philipp Lorber & Michaela Rohrbach